About Spray Foam Insulation

Spray Foam Insulation saves

You Money and Pays for Itself

Spray Foam Insulation saves on energy costs and lowers

utility bills. Spray Foam Insulation is used to seal the entire

“building envelope” of your home to prevent air and moisture

infiltration. The US Department of Energy (DOE) studies show that 40% of

your home’s energy is lost due to air infiltration. This air infiltrates

the home in the form of drafts through walls sockets, windows and

doorways. Often times no expensive building wrap or additional

vapor protection is required during construction when using Spray Foam

Insulation, saving money yet again.

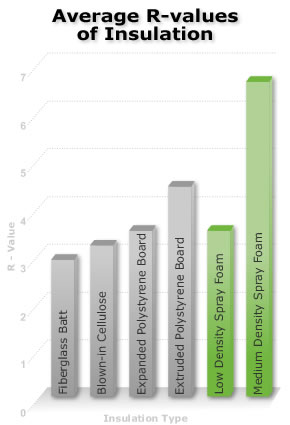

High R-Value

Sprayed polyurethane foam has an aged R-value of

approximately 6.0 per 1 inch thickness (depending on the particular

formulation and application, higher values have been achieved), enabling

it to provide more thermal resistance with less material than any other

type of commercial insulation material. Spray Foam Insulation systems

are frequently used to insulate and protect a wide variety of

residential, commercial, and industrial buildings.

Prevents Air, Moisture and

Gas Infiltration

Studies have shown that as much as 40% of a building’s

total energy loss is due to air infiltration. Traditional fiberglass

insulation is only stapled, or placed into the wall cavities and does

not seal the stud and wall cavities from end to end, or top to bottom.

Air infiltration can pass through these gaps, making it far less

efficient than Spray Foam Insulation. Spray Foam Insulation not only

adheres to, but forms to the walls and floors to create a tight seal and

insulating barrier that stops this air leakage. Spray Foam Insulation

also boasts the highest R-value per inch than any other commercial

material, (upwards of R-7.0, compared with Fiberglass at R-3.5) making

your home more comfortable and less expensive to heat in the winter, and

cool in the summer.

Products used by Porter's Spray Foam

Open-Cell Spray Foam Insulation

*Most

common in home insulation

Open-cell spray foam insulation is spray applied in a liquid, expanding

to 100 times its volume. Once applied, the product cures within seconds,

filling every crack and gap. The tiny cells expand at such a rapid rate

that they break apart and fill with air, creating a soft, almost spongy

end product. The rapid expansion of open-cell foam creates a perfect

air-tight seal using less material than closed-cell foam, thereby

creating a lower cost per R-Value.

R-value of 3.7 per inch

Lowest cost among all types of foam

Excellent noise reduction and sound control

Common Applications

·

Stud walls

Attics

Air Sealing

Sound Control

Closed Cell Spray Foam Insulation

Closed-cell foam insulation is a more slowly

expanding product, resulting in an expansion of approximately 40 times

its original volume. The closed-cell nature of this type of foam creates

a tightly packed cell structure that is more rigid and dense than

open-cell foam, giving closed-cell foam a higher R-value per inch. With

closed-cell being four times the density of open-cell foam, the cost per

R-value is higher for closed-cell foam than that of open-cell foam

insulation.

R-Value of 6.8 per inch

Enhances structural integrity

Qualifies a vapor retarder at 2”

Common Applications

- Attics, Basements and Crawl Spaces

Stud and Exterior Walls

Metal Buildings

High Moisture Areas